Metrology, the science of measurement

“Metrology” comes from the ancient Greek “metre” and “treated” and corresponds to the science of measurement.

What is measuring?

To measure is to determine, to evaluate a quantity (length, mass, temperature, intensity of the electric current …), a fortiori unknown, according to a standard, using an instrument.

For this, the method used must be reliable and reproducible and the standard, the measuring instrument must be characterized.

What references are measured?

Since 1960, the International System of Units – the SI – has made it possible to describe all physical or chemical phenomena based on its units and quantities, and to ensure the unification of measurements on a global scale. The national references are the practical implementation of the definitions of each base unit and the higher-level references for the derived units. They are recognized by all the Member States of the Metre Convention.

The national laboratories deliver the first reference level, with the best uncertainty at the national level, for the 7 basic quantities, called “national references”:

| National references | Measured quantity | Derived units |

| Meter | length | Area, volume, plane angle… |

| Kilogram | mass | Strength, pressure, energy, difference in electrical potential… |

| Second | time | frequency… |

| Ampere | Intensity of electric current | Difference in electrical potential, electrical resistance… |

| Kelvin | temperature | Celsius temperature, thermal conductivity… |

| Candela | luminous intensity | luminous flux, illuminance |

| Mole | Amount of material | Concentration, catalytic activity |

References are essential and should offer guarantees on:

- Sustainability: their stability over time must be sufficient and adapted to the need for measurement

- Uniformity: sampling must not alter its accuracy

- Accessibility: the measure must be able to be carried out easily, by all, and when the need is formulated

- … and with the best possible accuracy of course!

At Mesurex, our metrology laboratory makes the measurement of more reliable:

- Temperature (-38°C to 1250°C)

- Force (50 N to 450 KN)

- Pressure (1 bar to 1000 bar)

- Humidity (10 to 95% RH from 10°C to 95°C)

The inevitable and necessary uncertainty

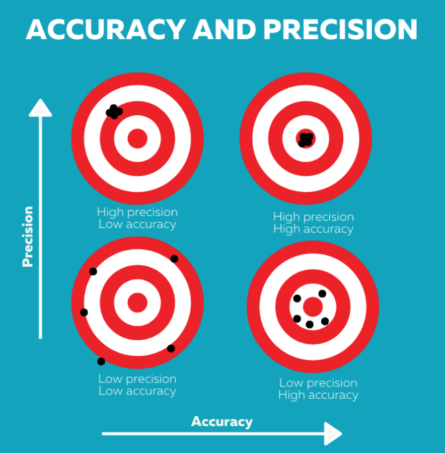

When measuring the quantity considered, there is always uncertainty about the accuracy and/or precision of the measurement. This uncertainty is linked to the measurement operations and considers all the parameters (“uncertainty balance”, which makes it possible to calculate the overall uncertainty of the measurement) which can induce an error on the final value: from the choice of the reference to the measurement range, through the experimental conditions. Uncertainty makes it possible to guarantee compliance with specifications or requirements (sanitary, industrial, climatic, etc.).

Each uncertainty calculation is specific to the measurement principle under consideration, and the method of establishing such a balance is described by the International Committee Joint with several Organizations for Metrology Guides.

What measurement guarantee?

Having the guarantee of making a good measurement means following its instrumentation and drifts by regular calibrations. This ensures the traceability of measurements made with the highest-level standards (national, international).

The references with the best uncertainties on a French scale are those issued by the French metrology network.

Each nation carries out its own chain of traceability, usually independently. In France, the first links in this chain are provided by LNE and the other member laboratories of the national metrology network. LNE, as a pilot, represents the France internationally. To ensure the validity of measurements, all national laboratories carry out comparisons of their references with their foreign counterparts, to ensure the consistency and universality of measurements worldwide.

At Mesurex, our measuring instruments are periodically checked by COFRAC accredited laboratories.

Metrology makes all the difference in the precision, reliability, and therefore the final quality of production. The study of measurement is particularly essential for industries where precision is crucial, such as aerospace, automotive, or medicine.

You want to know more about our metrology laboratory and our reliability capabilities of your measurements, visit our website and let us know your needs mesurex@mesurex.fr

#metrologie #measure # accuracy #precision #temperature #pressure #force #humidity #sensor