Mesurex + RICE by GRTgaz : designing the energy infrastructure of tomorrow

Despite the maturity of polyethylene (PE) electro-welding, some defects still escape detection by quality tests. Recent developments in in-situ non-destructive techniques aim to detect some of these defects after welding, hence too late.

Therefore, it is necessary to implement additional procedures to ensure, as early as possible, the quality of electro weldable fittings, and the appropriate amount of thermal energy for a good weld.

To ensure the quality of the weld, it is necessary to monitor the evolution of the temperature fields within the two components in contact, throughout the electro-welding cycle. Also, to map the temperature at the interface of an electro-welded assembly, GRTgaz’s energy research and innovation centre has developed a specific concept:

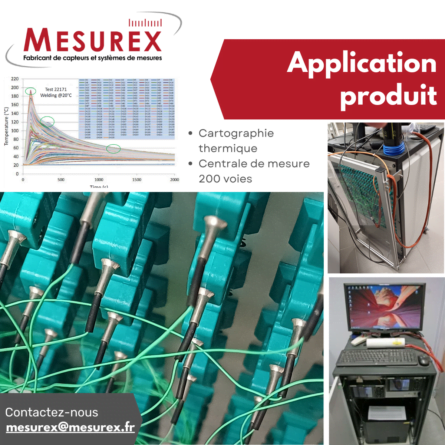

- a dummy pipe, instead of the real polyethylene pipe, made of a non-weldable polymer with thermal parameters close to those of PE, instrumented with 179 temperature sensors. The optimized sensor layout allows for real-time thermal mapping of the interface throughout the welding cycle. All 179 thermocouples are then connected to a data logger.

Based on the temperature field, an “inter-scattering parameter” is calculated at each location and compared to the reference values attached to the different PE grades. It then becomes possible to evaluate the quality of the weld in terms of design and welding conditions in advance. This technical solution can be implemented in the laboratory during the qualification or release phases of batches, or during production monitoring. It can also be used as an expert tool for geometrical and electrical sizing of EF fittings during the design phase.

To support this RICE research project towards new energy infrastructures, Mesurex instrumented the dummy pipe with supplied 179 single-strand Ø0.1mm K-type FTT thermocouples, and provided a 200-channel data acquisition unit, with data recording and processing and visualization on PC.

???? Your R&D Journey with Mesurex

Do you have R&D projects that involve thermal components? For more than 50 years, Mesurex has been a partner of major research centers in France and abroad. We are specialists in tailor-made solutions to support you in the development of your specific projects.

???? Let’s Elevate Your R&D Together! Contact us now : mesurex@mesurex.fr

#Innovation #ResearchAndDevelopment #WeldingTechnology #QualityAssurance #EnergyInfrastructure #PolyethyleneWelding #ThermalMapping