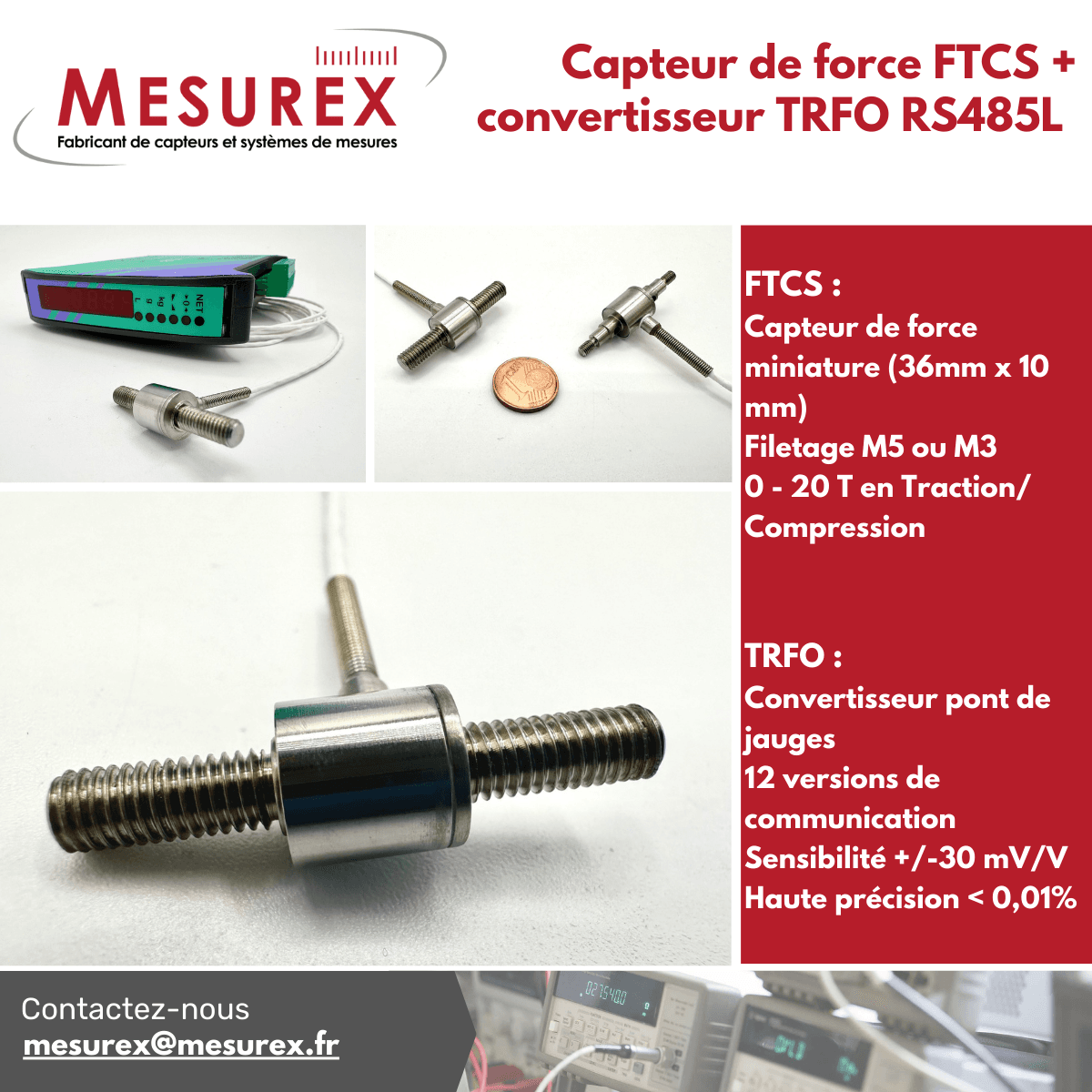

Combine the FTCS miniature force sensor + TRFO RS485L converter, and accelerate the performance of your tests!

18 December 2024

In a world where every micrometer and millinewton counts, our FTCS M5 miniature force sensor is a powerful engineering solution for transforming mechanical stresses into reliable and actionable data. It’s the ideal instrument for research on mechanical characterization, validation of resistance thresholds, fine control of gripping forces, and more.

Equipped with a standard M5 metric thread (also available in M3), this sensor is easily installed on a wide range of devices and offers numerous advantages:

- Robustness: entirely made of APX4, designed for demanding industrial environments

- Internal S-shape: allows for very low measurements relative to the measurement range

- Powerful despite its size: capable of handling significant forces (10 / 20 / 50 /100 / 200 N)

- Versatile: performs well in both tension and compression

- Compact and miniature: 36mm long, 10mm outer diameter

- Guaranteed precision: ±1%

- Thermally resistant: operational use from -30°C to 70°C

⚠️ Crucial point: This sensor only supports centered loads. Any misalignment will compromise accuracy and could damage the sensor. Consult us for expert mounting advice

However, there’s no point in having such an advanced sensor if you don’t ensure optimal data transmission! Therefore, don’t underestimate the importance of the converter, because it is just as crucial in the reliability, accuracy, durability, and ease of use of measurement data as the sensor itself.

To fully exploit the potential of the FTCS sensor, we recommend pairing it with the TRFO RS485L strain gauge converter, to brilliantly interface between your mechanical measurements (force, but also torque or pressure) and electrical signals.

In the demanding world of industrial measurement, the TRFO RS485L “stands out from the crowd”, combining technical precision with exceptional operational versatility (see datasheet aside).

The combination of the FTCS sensor + the TRFO RS485L converter creates a powerful synergy:

- Ultra-precise force/torque/pressure measurements in confined spaces

- Reliable and fast data transmission over long distances

- Simplified integration into your existing automation systems

Investing in the FTCS + TRFO RS485L duo means opting for a cutting-edge measurement solution from end to end, capable of meeting the strictest requirements of modern industry.

Consult-us to share your project & receive measurement expert’s advice : mesurex@mesurex.fr / 01 30 41 23 62

9 reasons to choose the TRFO RS485L over other strain gauge converters:

| Feature | Description |

|---|---|

| 1. Extensive communication options | 12 versions (RS485, CANopen, DeviceNet, CC-Link, Profibus DP, Modbus/TCP, Ethernet TCP/IP, Ethernet/IP, Profinet IO, EtherCAT, PowerLink, Sercos III) |

| 2. Excellent readability | LED display, 6 digits of 8 mm |

| 3. Very high accuracy | < 0.01% full scale |

| 4. Exceptional sensitivity | +/-30 mV/V |

| 5. Configurable analog output | 16 bit: 0/4-20 mA; 0-5/10 V; ±5/10 V |

| 6. Wide operating temperature range | -20 °C to +60 °C |

| 7. Large measurement capacity | Up to 8 sensors (350 Ω) |

| 8. Compact & practical | Compact design (115 x 25 x 120 mm), removable screw terminals, standard DIN rail mounting |

| 9. Laboratory calibration | Each module is calibrated in our metrology laboratory (with standards traceable to national standards) |