Implementation of sensors

At MESUREX, we understand that testing, validation, and trial campaigns can be costly, time-consuming, and risky in terms of achieving reliable results. That’s why we leverage years of expertise to deliver custom sensor instrumentation solutions tailored to your specific requirements. By integrating sensors directly onto your components, we ensure:

- Optimal sensor positioning for accurate and reliable measurements,

- Secure sensor placement throughout the testing process,

- Reduced handling and risk, minimizing potential damage to instruments and ensuring data integrity.

This approach significantly enhances testing efficiency, maximizes result quality, and streamlines your processes.

Comprehensive solutions for every physical measurement

MESUREX offers a wide range of sensors to meet diverse needs:

- Strain gauges,

- Force sensors,

- Pressure and temperature transmitters (thermocouples and RTD PT100 probes),

- Current, flow, and displacement sensors,

- And many more.

A complete service for ambitious projects

To address complex requirements, our instrumentation service includes:

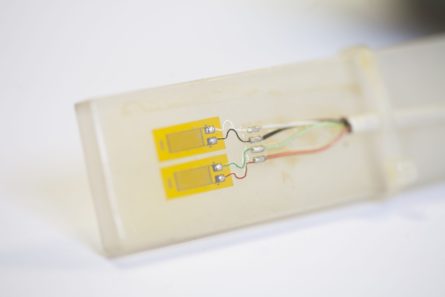

- A dedicated technical workshop for precise sensor integration,

- Facilities designed to accommodate large client components,

- A team of experts providing personalized support for every project.

End-to-End expertise

MESUREX delivers a comprehensive solution that includes:

- Custom sensor development, perfectly aligned with your specifications,

- Data acquisition systems, including acquisition units and autonomous dataloggers,

- Calibration services to ensure plug-and-play readiness and compliance with the strictest standards.

MESUREX is your trusted partner for high-performance, optimized instrumentation solutions.

Some examples of achievements

- Equipment of a system for the movement of Ariadne on its launch pad with recording and plotting via satellite the exact position and the effort control to fire the 1000T platform on the launcher.

- The measurement of displacement due to the climatic effects of arches and walls of historic monuments with remote measurements taken over several months and even years in some cases.

- The deformation of steel tubes buried underground (rock movements etc) linked to nuclear waste treatment, in this instrumentation we are the leaders, many strain gauges are applied for long-term studies.

- Instrumentation of helicopter turbines with pressure tubes and temperature sensors.

- Installation of thermocouple type temperature sensors on aircraft wing models.

- In the automotive industry, complete or partial line exhaust instrumentation, catalyst, particle filter in ceramic breads, “plastic” parts that revolve around the engine.

- Mapping of electronic cards and electric motors of different customers.